The Evolution of Aluminum Laser Cutter in Modern Fabrication

Rising demand for aluminum laser cutters in industrial applications

Since 2019, there's been quite a jump in how many manufacturers are using aluminum laser cutters these days. According to the Fabrication Technology Institute report from last year, adoption rates have gone up around 47%, especially noticeable in places like aerospace factories and transportation equipment makers. What's behind this trend? Well, industries need parts that are both light weight and strong enough to handle tough conditions. These parts often require really intricate shapes with tolerances tighter than 0.1 millimeter. Laser cutting works exceptionally well with those 6xxx series aluminum alloys that most industries rely on anyway since they account for nearly two thirds of all aluminum used in manufacturing today. That's why so many shops now consider laser cutting an essential part of their production process when working with aluminum materials.

Advantages over traditional machining: Speed, precision, and versatility

CNC-driven fiber laser systems achieve 4x faster cutting speeds than waterjet methods while maintaining ±0.05mm accuracy across 2-25mm thick sheets. Unlike mechanical machining that struggles with warping, laser processing eliminates tool wear issues and reduces material waste by 40% in automotive prototyping applications.

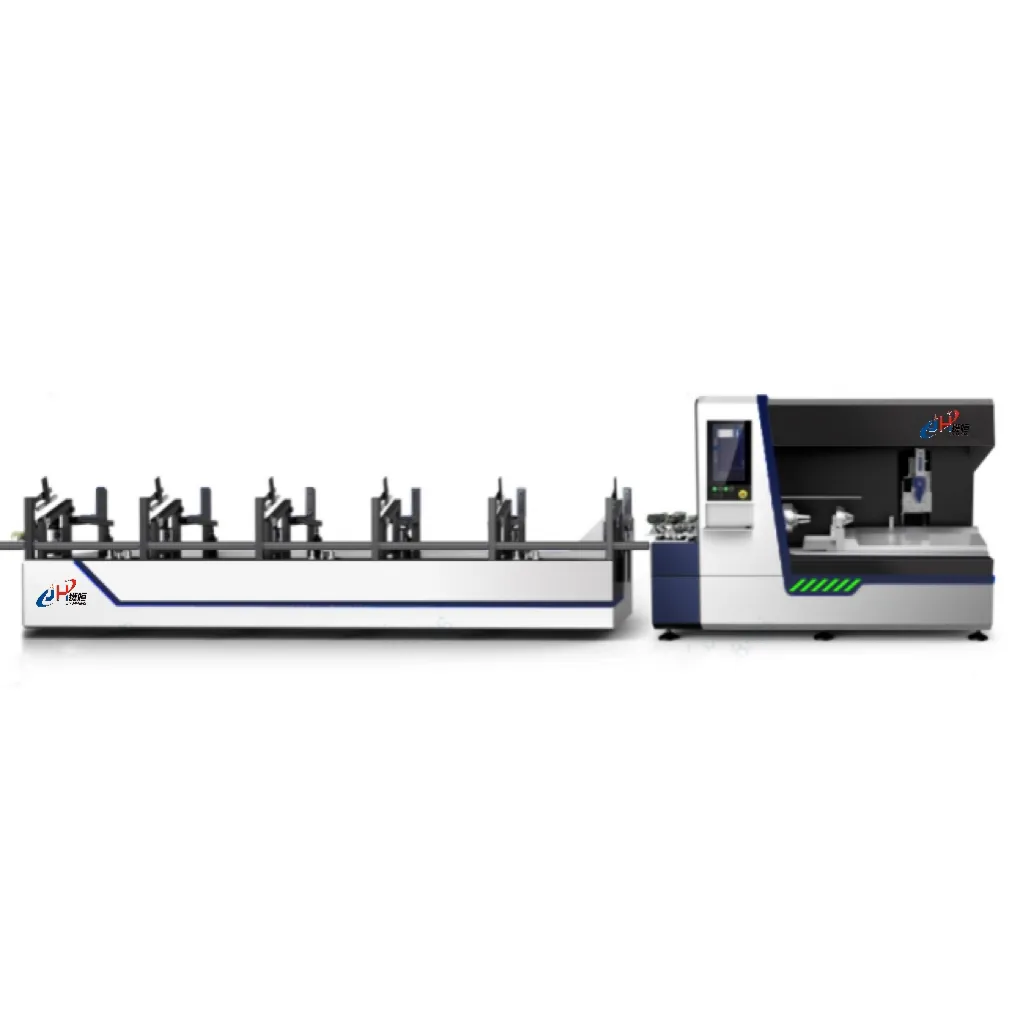

The role of automation and CNC integration in complex metal fabrication

Automated loading/unloading systems coupled with adaptive optics technology enable 24/7 production of intricate aluminum components with 99.8% repeatability. Recent advancements in beam modulation techniques have reduced cycle times by 35% while achieving surface roughness values below Ra 1.6 μm, surpassing aerospace finishing standards AS9100.

Core Principles of Precision in Aluminum Laser Cutting

Key Factors Influencing Cutting Accuracy in Aluminum Materials

Aluminum's thermal conductivity (237 W/m·K) and reflectivity (≈90% at 1 μm wavelength) demand specialized laser control systems to maintain cutting precision. Modern aluminum laser cutters compensate for these properties through adaptive beam modulation and real-time temperature monitoring, achieving positional accuracy within ±0.01 mm according to recent industry analyses.

Cutting Tolerances, Edge Quality, and Surface Finish as Performance Benchmarks

Tight tolerances below 0.05mm Ra surface roughness are now achievable through fiber laser systems, with kerf widths as narrow as 0.15mm in 3mm-thick 6061 alloy. As demonstrated in aerospace component studies, this eliminates secondary operations for 78% of machined parts while maintaining tensile strength integrity.

Impact of Laser Parameters: Power, Speed, Focus, and Beam Mode

Parameter optimization requires balancing four interdependent variables:

- Power: 4–6 kW ideal for 1–10mm sheets (prevents dross formation below 0.3mm)

- Speed: 15–25 m/min prevents heat accumulation in thin gauges

- Focal depth: –0.5 mm to +1.2 mm range for consistent vaporization

- Beam mode: Single-mode lasers reduce HAZ width by 40% vs multimode

Trade-Offs Between Cutting Speed and Dimensional Accuracy

Increasing feed rates beyond 30 m/min induces a 0.02 mm accuracy loss per 5 m/min acceleration in 5000-series alloys. However, advanced motion control systems can mitigate this trade-off through predictive path correction algorithms, maintaining <0.035 mm deviation up to 45 m/min cutting speeds.

Fiber Laser Technology: The Superior Choice for Aluminum Cutting

Why Fiber Lasers Outperform CO2 and YAG Systems on Reflective Metals

According to research from the Advanced Manufacturing Research Centre in 2023, fiber lasers are about 30 percent more efficient at cutting aluminum than traditional CO2 systems. What makes this possible? Well, fiber lasers operate at a wavelength of around 1.08 micrometers, which means they get absorbed three times better by aluminum materials compared to those old CO2 lasers that emit at 10.6 micrometers. And this actually translates into real world benefits too. For instance, when working with 3mm thick sheets, fiber lasers can cut at speeds reaching up to 40 meters per minute while using roughly 20% less power overall. This matters because aluminum has always been tricky to work with due to its tendency to reflect laser beams. Most CO2 systems end up losing over 45% of their beam energy through these reflections, making them much less effective for aluminum cutting applications.

Beam Quality and Spot Size Control in High-Reflectivity Environments

Precision-focused fiber laser cutters maintain beam diameters under 20 microns through proprietary collimation optics, enabling kerf widths as narrow as 0.1 mm. Real-time adaptive optics compensate for thermal lensing effects that plague YAG systems, ensuring consistent focus depth within ±0.05 mm—critical for aerospace-grade aluminum parts requiring ±0.1 mm positional accuracy.

Overcoming Challenges of Reflectivity and Thermal Conductivity in Aluminum

Modern systems integrate pulsed operation modes that reduce heat accumulation by 60% compared to continuous-wave cutting. Anti-reflection sensors monitor back-reflected light intensity, automatically adjusting pulse durations below 1 ms to prevent optical damage. Gas-assisted cutting with nitrogen (purity >99.95%) reduces oxide formation by 80% while improving heat dissipation in 6xxx-series aluminum alloys.

Case Study: Aerospace Component Manufacturing Using Fiber-Based Aluminum Laser Cutters

A 2024 analysis of aircraft bracket production revealed fiber laser systems reduced cycle times by 52% compared to CO₂ alternatives while achieving 99.97% dimensional compliance with AS9100 standards. The technology’s <0.05 mm repeatability enabled consolidation of 14 welded subcomponents into single 6061-T6 aluminum pieces, cutting material waste by 37% in high-volume aerospace applications.

Achieving High Complexity and Intricate Designs in Aluminum

Design Flexibility: Enabling Complex Geometries with Micron-Level Repeatability

Today's aluminum laser cutters can hit around ±5 microns repeatability thanks to their smart beam control systems and constant monitoring capabilities. What used to be considered impossible with older cutting techniques is now achievable with these advanced machines. According to research published last year in the Journal of Advanced Manufacturing, fiber lasers cut down on shape errors in aluminum parts by roughly two thirds when compared to plasma cutting methods. The level of accuracy makes them ideal for specialized applications such as tiny heat exchangers with microscopic channels or radio frequency shielding components where positioning needs to stay within just under 6 microns tolerance. Manufacturers working on high precision projects are increasingly turning to these systems for their unmatched consistency.

Applications in Industries Requiring Intricate Aluminum Parts (e.g., Aerospace, Electronics)

Aerospace companies have started turning to aluminum laser cutting technology for making those tiny cooling holes in turbine blades. These holes measure between 0.08 to 0.12 millimeters across, packed at around 300 per square centimeter density area. That's roughly 40 percent better than what EDM methods could manage back in the day. Moving over to electronics manufacturing, fast galvo laser systems are creating intricate 0.5 mm spaced trace patterns right on aluminum surfaces without causing any unwanted warping from heat exposure. Pretty impressive stuff when you think about it. And don't forget the medical device field either, where manufacturers claim nearly perfect results with their implantable parts made from aluminum. They're hitting about 98% success rate on first attempts for components that need walls as thin as 50 micrometers. Makes sense why so many industries are getting excited about these new laser capabilities lately.

Material Considerations: How Aluminum’s Thermal Properties Affect Laser Processing

| Parameter | Optimal Range for 6061-T6 | Impact on Cut Quality |

|---|---|---|

| Beam Focus | +0.2 mm to –0.1 mm | Controls dross formation |

| Pulse Frequency | 500–2000 Hz | Minimizes HAZ (<0.15 mm) |

| Assist Gas Pressure | 12–15 bar (Nitrogen) | Prevents aluminum re-deposition |

Aluminum’s high thermal conductivity (229 W/m·K) necessitates pulsed cutting at 2–5 m/min speeds to maintain 0.01°C/μm thermal gradients. Recent trials show dual-gas systems (helium + nitrogen) improve edge perpendicularity by 27% in 10 mm thick plates.

FAQs About Aluminum Laser Cutting

Q: Why is laser cutting preferred over traditional machining for aluminum?

A: Laser cutting offers speed, precision, and reduces material waste, making it more efficient than traditional machining, particularly for complex aluminum parts.

Q: What advantages do fiber lasers have over CO2 systems?

A: Fiber lasers are more efficient—especially at absorbing energy in aluminum—which leads to faster cutting speeds, reduced power usage, and less beam reflection compared to CO2 systems.

Q: Can aluminum laser cutting handle intricate or complex designs?

A: Yes, modern fiber laser technology allows for high precision and micron-level accuracy, ideal for intricate designs in industries like aerospace and electronics.