You Can Make Clean, Flawless, and Strong Welds with Unmatched Automation

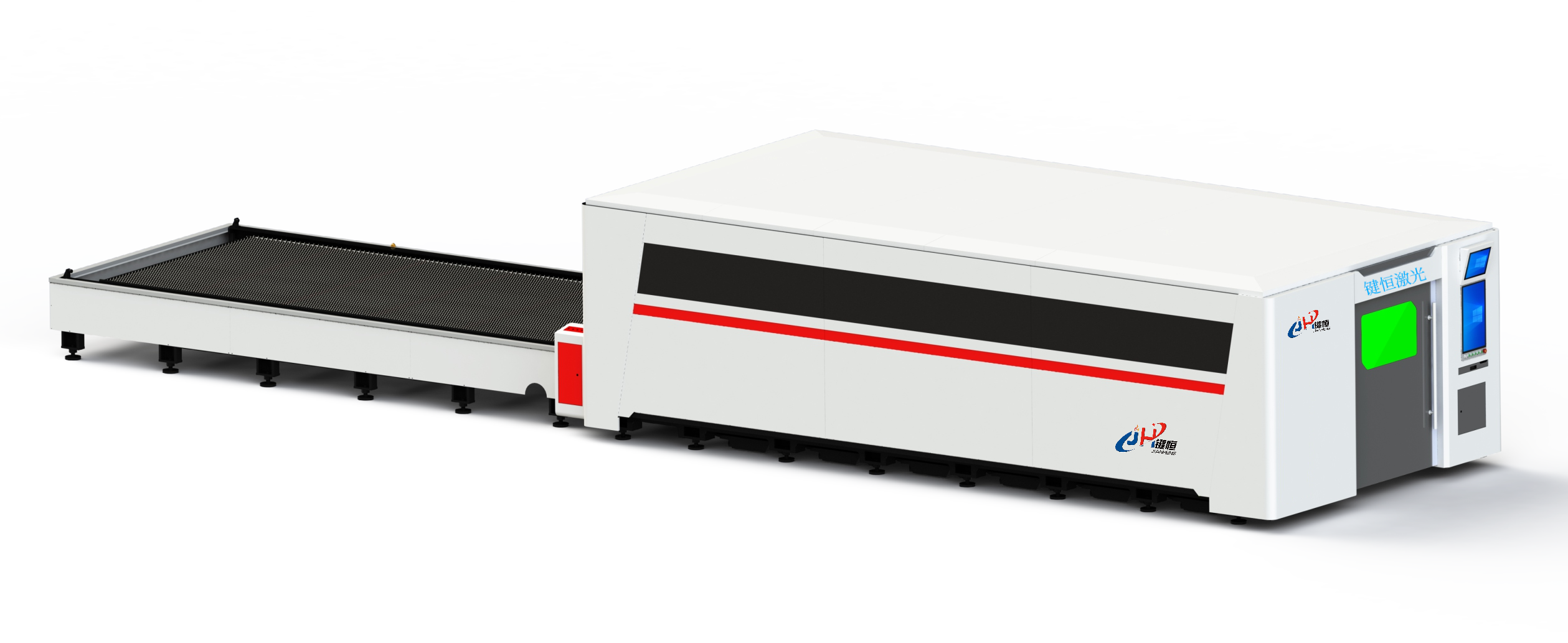

Introducing the innovation of High-Speed, Precision Fabless Industries, Automatic Laser Welder - designed for the precision manufacturer who demands speed, accuracy, repeatability, and a human free operation. The Automatic Laser Welder is designed for high volume production needing 100% automation. This will allow you to make clean, repeatable, spatter free, and low heat input welds. When working with delicate medical components, reflective metals (aluminum, copper), and complex automotive weldments this automatic laser welder will take the human aspect out and give maximum throughput. Moreover, the system does not compromise quality.