The Evolution and Impact of Laser Welding Machine Technology

How laser welding technology is reshaping industrial production

Laser welding has really changed how things get made in factories today because it lets manufacturers join materials with incredible accuracy. The process works by concentrating intense beams of light onto surfaces, creating welds that are both stronger and cleaner compared to what we used to do with conventional techniques. Factories report getting better results on their first attempt at welding, which means fewer rejects and less wasted material. What makes this technology stand out is its ability to handle super fine details on sensitive parts such as those found in smartphones or surgical instruments. When switching between different types of metals during production runs, there's no need to stop and change tools since lasers adapt so easily. Plus, since they generate less heat overall, important characteristics of the base materials stay intact while also saving power costs. Most plants now run these automated laser stations 24/7, which dramatically boosts daily production numbers. For anyone running a shop floor where both speed and perfection matter equally, investing in laser welding just makes good business sense.

Integration of non-contact welding processes in high-speed manufacturing

Laser welding that doesn't require contact works really well in fast production settings because there's no wearing down of physical tools involved. Factories can keep producing parts at amazing speeds, sometimes going over 10 meters per minute while still keeping quality pretty much the same throughout. One big plus is that nothing actually touches the material being worked on, so contamination becomes a thing of the past. These days most machines come equipped with monitoring systems that tweak power levels and focus points as they go along. Makes sense really, since materials aren't always perfectly uniform. Companies save loads of time that used to get eaten up replacing worn tips or doing cleanups between batches. The real magic happens when those high speed galvanometer scanners start moving laser beams around with incredible precision, talking about microns here. This kind of accuracy opens doors for manufacturers needing to produce complicated shapes quickly, which explains why auto plants have been adopting this technology so aggressively lately.

Throughput improvements with Laser Welding Machine adoption

Switching to laser welding machines can really boost efficiency in manufacturing shops. Research indicates that production throughput goes up around 40% when compared to traditional welding techniques. Why? Because these machines work much faster and eliminate a bunch of extra steps that normally slow things down. Another big plus is that they cut down on post-weld cleaning needs by nearly three quarters thanks to how accurately they control heat application. Factories running production lines see better overall equipment effectiveness too since there are fewer interruptions during operation. Plus, material waste gets dramatically reduced because the lasers are so precise with their cuts. All these factors combined mean companies typically recoup their investment pretty quickly even though the upfront cost for laser systems tends to be higher than what conventional welders cost.

Core Advantages: Precision, Speed, and Quality in Laser Welding Processes

Minimizing Heat-Affected Zone (HAZ) for Superior Weld Quality

Laser welding that doesn’t require contact works really well in fast production settings because there's no wearing down of physical tools involved. Factories can keep producing parts at amazing speeds, sometimes going over 10 meters per minute while still keeping quality pretty much the same throughout. One big plus is that nothing actually touches the material being worked on, so contamination becomes a thing of the past. These days most machines come equipped with monitoring systems that tweak power levels and focus points as they go along. Makes sense really, since materials aren't always perfectly uniform. Companies save loads of time that used to get eaten up replacing worn tips or doing cleanups between batches. The real magic happens when those high speed galvanometer scanners start moving laser beams around with incredible precision, talking about microns here. This kind of accuracy opens doors for manufacturers needing to produce complicated shapes quickly, which explains why auto plants have been adopting this technology so aggressively lately.

Throughput improvements with Laser Welding Machine adoption

Switching to laser welding machines can really boost efficiency in manufacturing shops. Research indicates that production throughput goes up around 40% when compared to traditional welding techniques. Why? Because these machines work much faster and eliminate a bunch of extra steps that normally slow things down. Another big plus is that they cut down on post-weld cleaning needs by nearly three quarters thanks to how accurately they control heat application. Factories running production lines see better overall equipment effectiveness too since there are fewer interruptions during operation. Plus, material waste gets dramatically reduced because the lasers are so precise with their cuts. All these factors combined mean companies typically recoup their investment pretty quickly even though the upfront cost for laser systems tends to be higher than what conventional welders cost.

Core Advantages: Precision, Speed, and Quality in Laser Welding Processes

Minimizing Heat-Affected Zone (HAZ) for Superior Weld Quality

Laser welding that doesn't require contact works really well in fast production settings because there's no wearing down of physical tools involved. Factories can keep producing parts at amazing speeds, sometimes going over 10 meters per minute while still keeping quality pretty much the same throughout. One big plus is that nothing actually touches the material being worked on, so contamination becomes a thing of the past. These days most machines come equipped with monitoring systems that tweak power levels and focus points as they go along. Makes sense really, since materials aren't always perfectly uniform. Companies save loads of time that used to get eaten up replacing worn tips or doing cleanups between batches. The real magic happens when those high speed galvanometer scanners start moving laser beams around with incredible precision, talking about microns here. This kind of accuracy opens doors for manufacturers needing to produce complicated shapes quickly, which explains why auto plants have been adopting this technology so aggressively lately.

Throughput improvements with Laser Welding Machine adoption

Switching to laser welding machines can really boost efficiency in manufacturing shops. Research indicates that production throughput goes up around 40% when compared to traditional welding techniques. Why? Because these machines work much faster and eliminate a bunch of extra steps that normally slow things down. Another big plus is that they cut down on post-weld cleaning needs by nearly three quarters thanks to how accurately they control heat application. Factories running production lines see better overall equipment effectiveness too since there are fewer interruptions during operation. Plus, material waste gets dramatically reduced because the lasers are so precise with their cuts. All these factors combined mean companies typically recoup their investment pretty quickly even though the upfront cost for laser systems tends to be higher than what conventional welders cost.

Core Advantages: Precision, Speed, and Quality in Laser Welding Processes

Minimizing Heat-Affected Zone (HAZ) for Superior Weld Quality

Laser welding equipment produces joints that are roughly 70-75% stronger when working with different metal combinations such as aluminum and copper or steel mixed with magnesium. Rapid bursts keep the area affected by heat much smaller while minimizing heat-affected zones. In car manufacturing, auto plants are adopting this technology aggressively.

| Laser Type | Thickness Range | Speed (mm/s) | Common Applications |

|---|---|---|---|

| Laser Type | Thickness Range | Speed (mm/s) | Common Applications |

| Fiber-Hybrid | 1–8 mm | 10–30 | Battery terminals, compact housing seals |

Core Advantages: Precision, Speed, and Quality in Laser Welding Processes

Minimizing Heat-Affected Zone (HAZ) for Superior Weld Quality

Laser welding that doesn't require contact works really well in fast production settings because there’t wearing down of physical tools involved. Factories can keep producing parts at amazing speeds, sometimes going over 10 meters per minute while still keeping quality pretty much the same throughout. One big plus is that nothing actually touches the material being worked on, so contamination becomes a thing of the past. These days most machines come equipped with monitoring systems that tweak power levels and focus points as they go along. Makes sense really, since materials aren’t always perfectly uniform. Companies save loads of time that used to get eaten up replacing worn tips or doing cleanups between batches. The real magic happens when those high speed galvanometer scanners start moving laser beams around with incredible precision, talking about microns here. This kind of accuracy opens doors for manufacturers needing to produce complicated shapes quickly, which explains why auto plants have been adopting this technology so aggressively lately.

Throughput improvements with Laser Welding Machine adoption

Switching to laser welding machines can really boost efficiency in manufacturing shops. Research indicates that production throughput goes up around 40% when compared to traditional welding techniques. Why? Because these machines work much faster and eliminate a bunch of extra steps that normally slow things down. Another big plus is that they cut down on post-weld cleaning needs by nearly three quarters thanks to how accurately they control heat application. Factories running production lines see better overall equipment effectiveness too since there are fewer interruptions during operation. Plus, material waste gets dramatically reduced because the lasers are so precise with their cuts. All these factors combined mean companies typically recoup their investment pretty quickly even though the upfront cost for laser systems tends to be higher than what conventional welders cost.

Industrial Applications of High-Power Laser Welding Machines

High-power laser welding machines have become indispensable in sectors demanding precision, speed, and structural integrity. Their ability to fuse thick-section materials (up to 25mm penetration depth) at speeds exceeding 10 meters per minute has redefined fabrication standards for shipbuilding, energy infrastructure, and heavy machinery components.

Advancements in High-Power Laser Welding for Thick-Section Materials

The latest generation of laser systems comes equipped with adaptive optics plus real-time monitoring features that keep the beam focused even on rough or irregular surfaces. This means manufacturers can achieve consistently good welds in steel plates as thick as 30 millimeters. Research from the Advanced Manufacturing Institute back in 2024 found something pretty impressive too. These new systems cut down on those pesky porosity defects by around half compared with what we see using older techniques for making pressure vessels. That kind of improvement makes a big difference in industrial applications where structural integrity matters most.

Applications in Automotive, Aerospace, and Electronics Manufacturing

- Automotive: Laser welding machines join EV battery trays and aluminum body panels with 0.1mm positional accuracy, contributing to a 30% reduction in production time for electric vehicle components.

- Aerospace: Titanium airframe welds achieve tensile strengths of 1,200 MPa while minimizing heat-affected zones (HAZ), critical for fatigue-resistant aircraft structures.

- Electronics: Pulsed fiber lasers create 50ϼm-wide seams in circuit boards, enabling hermetic seals for 5G sensor housings without damaging adjacent components.

Comparative Analysis: Laser vs. Traditional Arc Welding in Heavy Industries

Laser systems outperform arc welding in three key areas:

- Distortion Control: 80% lower thermal distortion in steel beams over 10 meters.

- Operating Costs: 45% less energy consumption per meter of weld in pipeline fabrication.

- Defect Rates: 60% fewer weld repairs in offshore platform construction due to precise parameter control.

While arc welding retains advantages for field repairs, laser welding machines now dominate fixed-position heavy fabrication with their repeatable, high-tolerance outputs.

Automation and the Future: Robotic Laser Welding and Smart Manufacturing

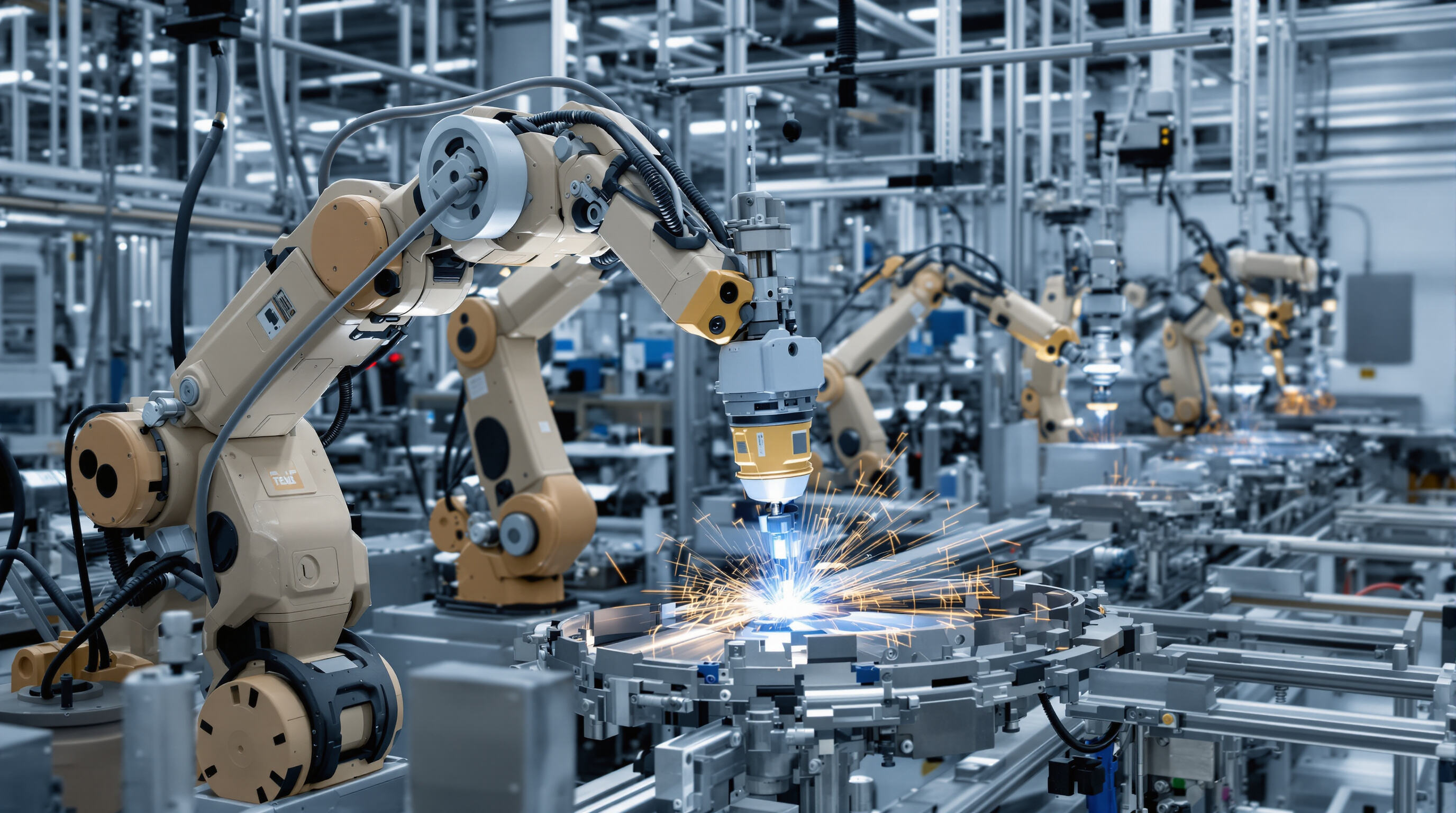

Working mechanism of robotic laser welding systems

In robotic laser welding setups, articulated arms work together with powerful lasers via specialized optical systems that deliver the beam precisely where needed. The system follows pre-programmed routes as it moves across complicated joints, and during this process, various sensors keep track of how well each weld is forming right then and there. Because it doesn't require physical contact between components, these systems can hit incredibly tight tolerances while putting out very little heat. This makes them particularly good for joining tricky materials such as aluminum alloys or thin sheet metal parts that would warp under traditional methods.

Benefits of laser welding in manufacturing efficiency through automation

Automated laser welding boosts production throughput by 40–60% compared to manual methods while eliminating human error variability. Key advantages include:

- 24/7 operation with minimal supervision

- Reduced scrap rates through consistent weld penetration

- Flexibility for rapid product changeovers

- Elimination of post-weld finishing in 85% of applications

Balancing cost and ROI: High initial investment vs. long-term gains

While robotic Laser Welding Machine installations require significant upfront investment ($150k–$500k), manufacturers typically achieve ROI within 18–36 months through:

- 30–50% reduction in labor costs

- 25% lower energy consumption versus arc welding

- 60% decrease in material waste

- Extended equipment lifespan with predictive maintenance

The transition to automated welding solutions delivers 3–7X productivity gains that offset capital expenditure within two production cycles according to industry benchmarks.

Innovations and Challenges: Dissimilar Metal Joining and Next-Gen Lasers

Breakthroughs in Dissimilar Metal Welding Using Precision Laser Welding Machines

The latest generation of laser welding equipment produces joints that are roughly 70-75% stronger when working with different metal combinations such as aluminum and copper or steel mixed with magnesium, which is quite a leap forward from what arc welding can manage. Traditional welding approaches often lead to brittle intermetallic formations between metals, but fiber lasers cut down on this problem by creating very short heat pulses lasting just 2 to 5 milliseconds. These quick bursts help keep the area affected by heat much smaller while still getting decent penetration depths around 12 millimeters deep. For car makers building electric vehicles, this level of control means they can attach battery terminal connections with copper and aluminum joined together at incredibly low porosity levels below 0.2%. This matters because differences in how these metals expand when heated used to cause about one in five weld failures in EV parts before these new techniques came along.

Role of Diode and Hybrid Lasers in Advanced Joining Applications

Diode lasers now dominate micro-welding applications requiring <50 µm beam diameters, particularly in electronics manufacturing for copper-nickel interconnects. A 2024 study comparing laser types reveals key performance differences:

| Laser Type | Thickness Range | Speed (mm/s) | Common Applications |

|---|---|---|---|

| Diode | 0.1–2 mm | 80–120 | Sensor components, thin foils |

| Fiber-Hybrid | 1–8 mm | 40–60 | Battery trays, heat exchangers |

| CO₂ | 5–25 mm | 10–30 | Power plant pipe welding |

Hybrid systems combining fiber and diode technologies reduce intermetallic formation by 58% in titanium-steel aerospace joints through adaptive power modulation.

Can Laser Welding Replace Resistance Welding? Analyzing the Controversy

While laser welding machines achieve 40% lower lifecycle costs than resistance welding over five years, two barriers persist:

- Material Limitations: Galvanized steel still shows 12–15% higher defect rates with lasers due to zinc vaporization

- Material Limitations: System installation costs and process complexity remain barriers for manufacturers seeking to transition from existing resistance methods.

However, automated laser systems now outperform resistance methods in flexible manufacturing environments, with a single robotic cell typically managing 12 or more workpieces simultaneously and reducing manual operator requirements by up to 80%.

FAQ

What is laser welding?

Laser welding is a technology that uses concentrated beams of light to join materials with high precision and strength, often used in industrial production for creating strong, clean welds.

How does laser welding benefit manufacturers?

Laser welding offers several benefits including improved accuracy, reduced waste, faster production, and less energy consumption. Its ability to handle delicate parts without stopping and adaptability between materials makes it ideal for manufacturing environments.

Can laser welding be used on different types of metals?

Yes, laser welding can adapt to various metals without needing to stop or change tools, making it highly versatile in production processes.

How does laser welding improve production throughput?

By working faster and eliminating unnecessary steps, laser welding improves production throughput by around 40% compared to traditional techniques. It also reduces post-weld cleaning and material waste.

What industries benefit from high-power laser welding machines?

Industries such as shipbuilding, energy infrastructure, automotive, aerospace, and electronics manufacturing benefit significantly from high-power laser welding machines due to their precision, speed, and capabilities.

Can laser welding replace resistance welding?

While laser welding can achieve lower lifecycle costs and higher flexibility in many cases, material limitations and throughput trade-offs still pose challenges in replacing resistance welding for specific applications.

What is robotic laser welding?

Robotic laser welding systems use articulated arms and specialized optical systems to precisely deliver laser beams to weld joints, providing tight tolerances and minimal heat distribution.

Table of Contents

- The Evolution and Impact of Laser Welding Machine Technology

- Core Advantages: Precision, Speed, and Quality in Laser Welding Processes

- Core Advantages: Precision, Speed, and Quality in Laser Welding Processes

- Core Advantages: Precision, Speed, and Quality in Laser Welding Processes

- Core Advantages: Precision, Speed, and Quality in Laser Welding Processes

- Industrial Applications of High-Power Laser Welding Machines

- Automation and the Future: Robotic Laser Welding and Smart Manufacturing

- Innovations and Challenges: Dissimilar Metal Joining and Next-Gen Lasers

-

FAQ

- What is laser welding?

- How does laser welding benefit manufacturers?

- Can laser welding be used on different types of metals?

- How does laser welding improve production throughput?

- What industries benefit from high-power laser welding machines?

- Can laser welding replace resistance welding?

- What is robotic laser welding?