Superior Precision and Accuracy with Laser Welding Machine

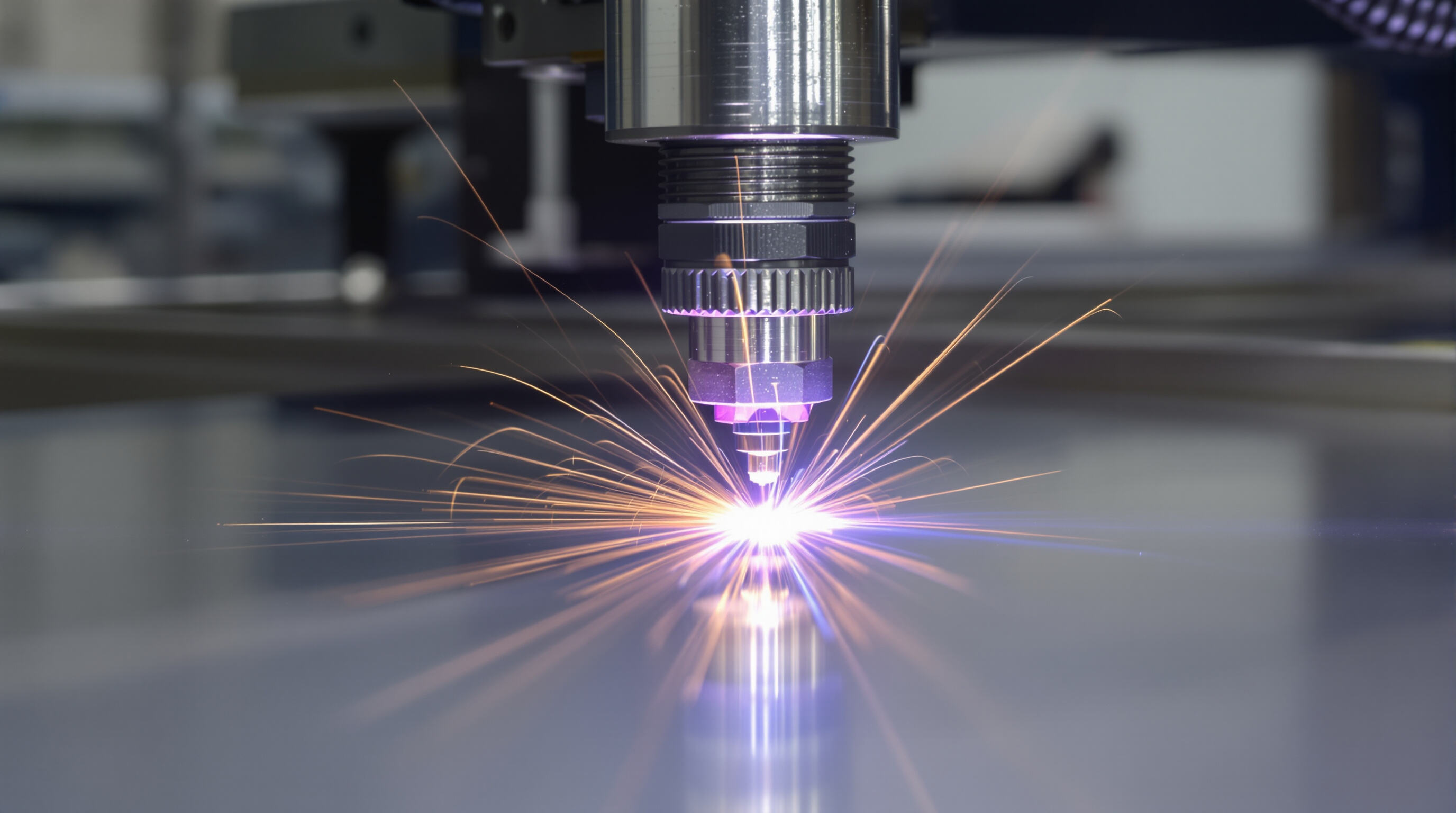

How High Energy Density and Beam Focus Enable Micron-Level Welding

Laser welding equipment gets down to the micron level thanks to how they concentrate energy and control where the beam hits. These machines actually focus the laser light into spots smaller than 0.1mm across, which means they deliver super intense heat right where needed. The result? Welds that sit exactly where they should, usually within about 5 microns of target. Unlike traditional arc welding that often warps materials because of uneven heating, lasers let operators dial in just the right amount of heat for each spot. And since there's no physical contact involved, these systems can maintain proper penetration depth even when working on complicated shapes. The end product tends to have much cleaner seams too, so factories spend less time doing cleanup work after welding.

Applications in High-Tolerance Industries: Automotive, Aerospace, and Medical Devices

Laser welding brings an incredible level of precision that many industries just can't live without when making parts that absolutely must work right every time. Car companies use this tech all over the place, especially for those tiny fuel injectors that need to hold up against pressures exceeding 200 bars without so much as a single drop leaking out. Up in the skies, aircraft engineers turn to lasers when fixing turbine blades because even the tiniest deviation from perfect welds matters here we're talking about keeping things within a hair's breadth tolerance of 0.05mm. For medical equipment makers, laser welding is practically a lifesaver literally. They need those pacemaker cases sealed completely tight against body fluids, and surgical instruments joined together without any risk of particles getting loose inside someone during operations. What really stands out though is how consistently reliable this method stays batch after batch, which is exactly why most manufacturers will tell you meeting those tough ISO 13485 and AS9100 requirements isn't just nice to have it's table stakes nowadays.

Strategy: Integrating Laser Welding for Critical Components Requiring Tight Tolerances

Getting laser welding right for those precision jobs means finding the sweet spot with all the parameters involved. Most folks start by doing some destructive tests on sample joints first, which helps figure out what works best for power duration usually somewhere between 1 and 20 milliseconds of pulse time and where exactly to focus the beam. During actual production, having vision systems that can track seams in real time becomes really important too. These systems need at least 10 micrometer resolution to catch any issues as they happen. When working with those tricky copper aluminum joints that show up so often in electric vehicle battery packs, special beam oscillation patterns become necessary to manage how intermetallic compounds form. And let's not forget about automated fixturing equipped with force feedback mechanisms. This kind of setup keeps parts aligned consistently across production runs, staying within that tight tolerance range of under 25 micrometers variance from start to finish.

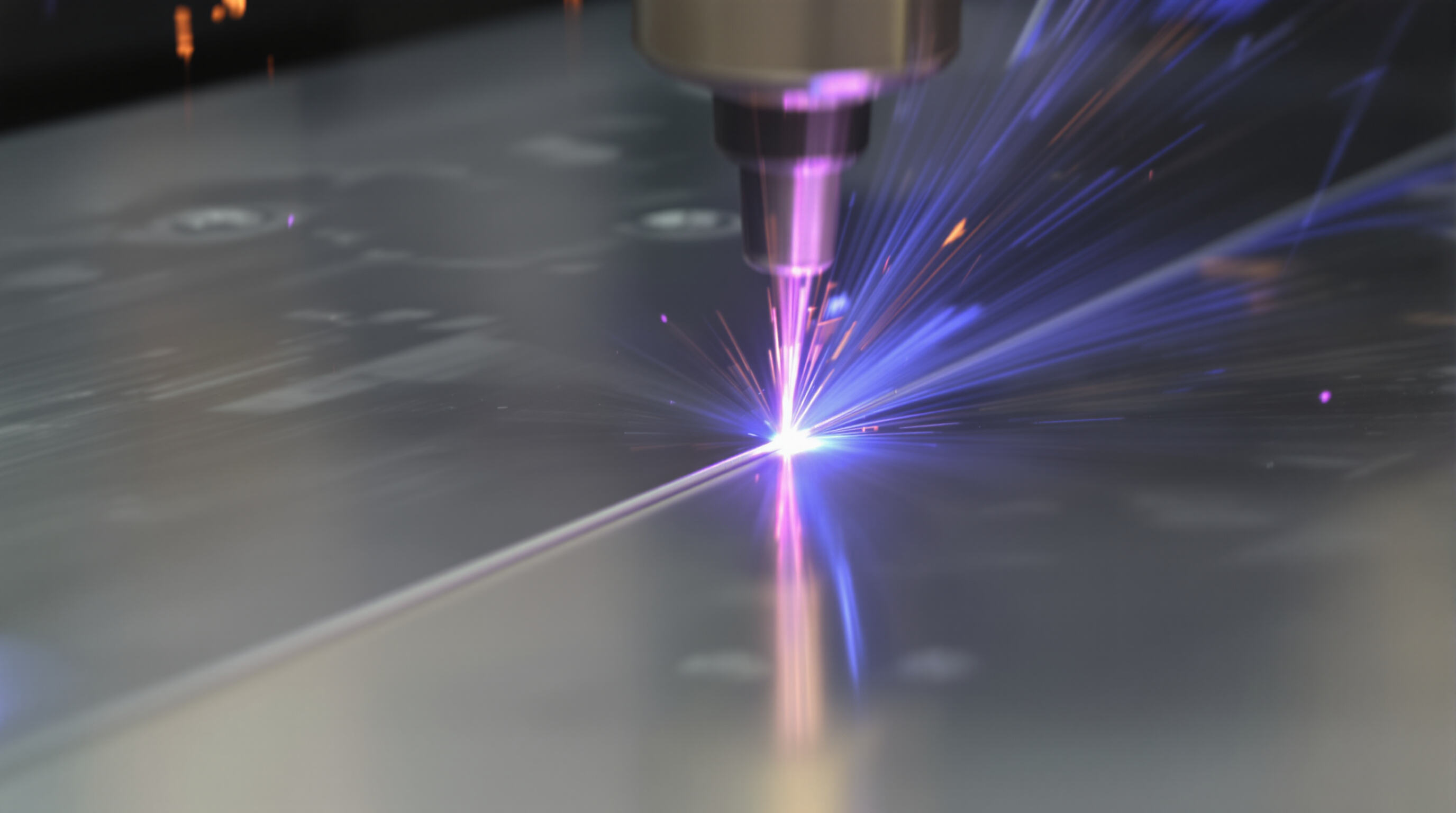

Minimized Heat Affected Zone and Reduced Distortion

Why Laser Welding Produces Smaller HAZ Compared to MIG/TIG Methods

The heat affected area when using laser welding is much smaller compared to MIG or TIG techniques because lasers concentrate their energy so tightly with beams measured in microns. Traditional arc welding spreads out heat over larger surfaces, which can make the HAZ around three times bigger. Laser equipment focuses the heat exactly where needed, cutting down on unwanted effects nearby. Research shows this focused approach cuts down on HAZ size somewhere between 60 to 90 percent based on thermal images taken during tests. What this means for materials is they retain their original characteristics better, and those annoying grain changes that happen with regular welding just don't occur as often.

Preventing Warping in Thin-Gauge Metals and Sensitive Assemblies

Laser welding creates a much smaller heat affected zone compared to traditional methods, which helps prevent warping issues in very thin metals under 1 mm thick. This matters a lot for things like delicate electronic parts or medical implants where even small distortions can be problematic. The way lasers focus their energy on such tiny areas basically stops those annoying thermal expansions that happen with MIG or TIG welding. Some aerospace companies have actually seen around 75 percent reduction in fixing warped titanium parts after they switched over to laser technology. Makes sense really because the controlled heating keeps everything dimensionally stable while still creating strong joints that hold up well over time.

Use pulsed waveforms for heat-sensitive applications, allowing inter-pulse cooling. Implement beam oscillation to distribute energy evenly, and always conduct trial welds with thermocouple monitoring to validate thermal profiles before full-scale production.

Faster Welding Speeds and Higher Production Throughput

Laser welding machines deliver unmatched production velocity compared to traditional methods, transforming manufacturing efficiency. By concentrating high-energy beams that instantly melt and fuse materials, these systems eliminate the slower heating cycles of arc-based processes. This fundamental advantage enables manufacturers to achieve throughput previously unattainable with conventional welding equipment.

Laser vs. Traditional Welding: Speed Advantages in High-Volume Manufacturing

On modern automotive and aerospace assembly lines, laser welding can clock in at around four to five times the speed of those old MIG/TIG techniques, based on what we're seeing from industry reports coming out in 2025. What makes this method so appealing is that it doesn't need electrodes swapped out or filler materials adjusted during operation, which means machines can run nonstop without interruption. For manufacturers dealing with massive production volumes, especially when making battery trays for electric vehicles, the difference is night and day. A single laser setup might weld hundreds of seams in an hour while traditional shops would need several different stations just to keep up with similar output levels.

Leveraging Pulsed and Continuous Wave Modes for Process Efficiency

Operators maximize throughput by selecting optimal energy delivery modes:

- Pulsed mode provides controlled, intermittent energy bursts for delicate joints in electronics

-

Continuous wave mode sustains uninterrupted power for deep-penetration welds in structural components

Modern fiber lasers (up to 10 kW output) allow real-time switching between modes, reducing process changeover time by 30% while maintaining weld integrity across varying material thicknesses.

Case Study: Achieving 40% Increased Output in an Industrial Fabrication Line

A shipbuilding manufacturer implemented dynamic beam laser technology to replace submerged arc welding. By optimizing focal points and power parameters, they achieved:

| Metric | Improvement |

|---|---|

| Welding speed | +40% |

| Energy consumption | -60% |

| Filler material usage | -90% |

| This industrial transformation demonstrates how laser systems enable scalable production growth while reducing quality standards. The technology's minimal post-processing requirements further accelerated component throughput by eliminating grinding and rework stages. |

Greater Versatility in Welding Dissimilar and Advanced Metals

Joining Challenging Material Combinations: Stainless Steel to Aluminum

Laser welding tech has broken through old limits when it comes to joining metals that just wouldn't play nice together before. Recent research published in Frontiers in Physics shows fiber lasers can weld stainless steel to aluminum with about 95% efficiency these days. That's pretty impressive considering this metal combo used to crack apart all the time with regular arc welding methods. The secret lies in being able to tweak laser wavelengths specifically for each material type. Aluminum needs around 1 micrometer wavelength because it reflects light so much, whereas steel works better with the longer 10.6 micrometer setting. Plus, the focused energy delivery helps prevent those pesky intermetallic compounds from forming at the joint. Boat builders are already taking advantage of this advancement to construct hulls that resist corrosion better and weigh nearly 18% less than what they could make using conventional techniques back in the day.

Adjusting Wavelength and Power for Optimal Material Compatibility

| Parameter | Effect on Material Compatibility | Industrial Application Example |

|---|---|---|

| Short wavelength (1µm) | Reduces reflectivity in aluminum alloys | Battery tray welding for EVs |

| High power (4kW+) | Enables 12mm penetration in titanium | Aircraft engine component fabrication |

| Adjustments to laser parameters allow manufacturers to address unique material behaviors. For instance, reducing power density to 10³ W/cm² prevents burn-through in 0.5mm copper sheets, while pulsed modes at 500Hz eliminate porosity in magnesium joints. |

Overcoming Thermal Expansion Mismatch with Hybrid Laser-Arc Techniques

When it comes to joining different metals, hybrid laser-arc welding offers something special. It takes advantage of lasers' low heat input around 140 joules per millimeter while still benefiting from arc welding's ability to bridge gaps. This combination helps overcome the tricky issue of thermal expansion differences between copper and steel, which can be about 0.3 mm per mm. Field tests at several power plants have found that using this method cuts down on the need for extra machining work after welding by roughly 60%. What makes this technique particularly impressive is how quickly it switches between energy sources – just 0.1 seconds according to research published in Scientific Reports last year. This fast transition allows engineers to weld coolant pipes in nuclear reactors continuously, even though these components face thousands of thermal cycles over their operational lifespan.

Long-Term Cost Efficiency and Scalability in Smart Manufacturing

Balancing Initial Investment with ROI from Automation and Lower Labor Costs

Laser welding machines definitely cost more at first compared to older equipment, but companies save money over time thanks to automation and lower labor bills. These automated systems cut down on hands-on work and boost how much gets produced each day, so factories can move their workers onto jobs that actually matter more for business growth. Some research into updating factory setups shows that when manufacturers adopt smart tech, their workflow gets smoother and running costs drop without sacrificing product quality. Most businesses see their investment pay off within two to three years because they spend less on staff and waste fewer materials. This makes sense especially for places cranking out products in large quantities where every small saving adds up fast.

Improving Workplace Safety by Reducing Fumes, Radiation, and Manual Intervention

Laser welding equipment makes factory floors much safer for workers since they produce around 70 percent less smoke and cut down on radiation dangers when compared to traditional arc welding techniques. Modern laser systems are designed with enclosures that keep everything contained during the actual welding process, so operators aren't breathing in all those harmful particles or staring directly at blinding lights anymore. Plus, automated features mean less direct contact with scorching materials and electrodes, which cuts down on burn hazards, hand and wrist problems from constant repetition, and electrocution risks too. Factories adopting this tech report better safety records overall, plus savings money on accident-related expenses, fines for not following regulations, and insurance payouts for injured staff members.

Integrating Laser Welding Machines into Industry 4.0 and Automated Production Lines

Laser welding tech plays a key role in bringing Industry 4.0 to life on factory floors, especially when paired with smart IoT production systems. Modern laser welders send live data straight to central control panels, which helps factories predict equipment failures before they happen, keeps an eye on product quality, and lets operators tweak processes as needed. Factories report around a 30 to 40 percent drop in unexpected shutdowns thanks to this connection, plus they can grow their output simply by adding more modular automation units where needed. What makes laser welding stand out is how well it works with robotic arms and conveyor systems, creating manufacturing setups that can be quickly adjusted when switching between different products or production runs. This flexibility saves money and time during product changes.

FAQ

What is laser welding, and how does it work?

Laser welding is a process that uses a laser beam to fuse materials together. The laser provides a concentrated heat source, which melts the material in a small and precise area, allowing for highly accurate welds.

Which industries benefit from laser welding technology?

Industries like automotive, aerospace, and medical equipment manufacturing benefit significantly from laser welding due to its precision and consistency, which are critical for high-tolerance components.

What is the heat affected zone (HAZ) in welding?

The heat affected zone is the area of material that is altered by the welding process. Laser welding produces a smaller HAZ compared to conventional welding methods, minimizing distortion.

How does laser welding improve production efficiency?

Laser welding increases production efficiency by allowing faster welding speeds and reducing the need for post-weld processing, leading to higher throughput and less downtime.

Can laser welding machines be integrated into automated production lines?

Yes, laser welding machines are highly compatible with automated production lines and Industry 4.0 systems, facilitating data-driven manufacturing and efficient process management.