Laser Welding Machine of Core Principles and Technological Differences

How Laser Welding Machine Technology Works: From Beam Focus to Fusion

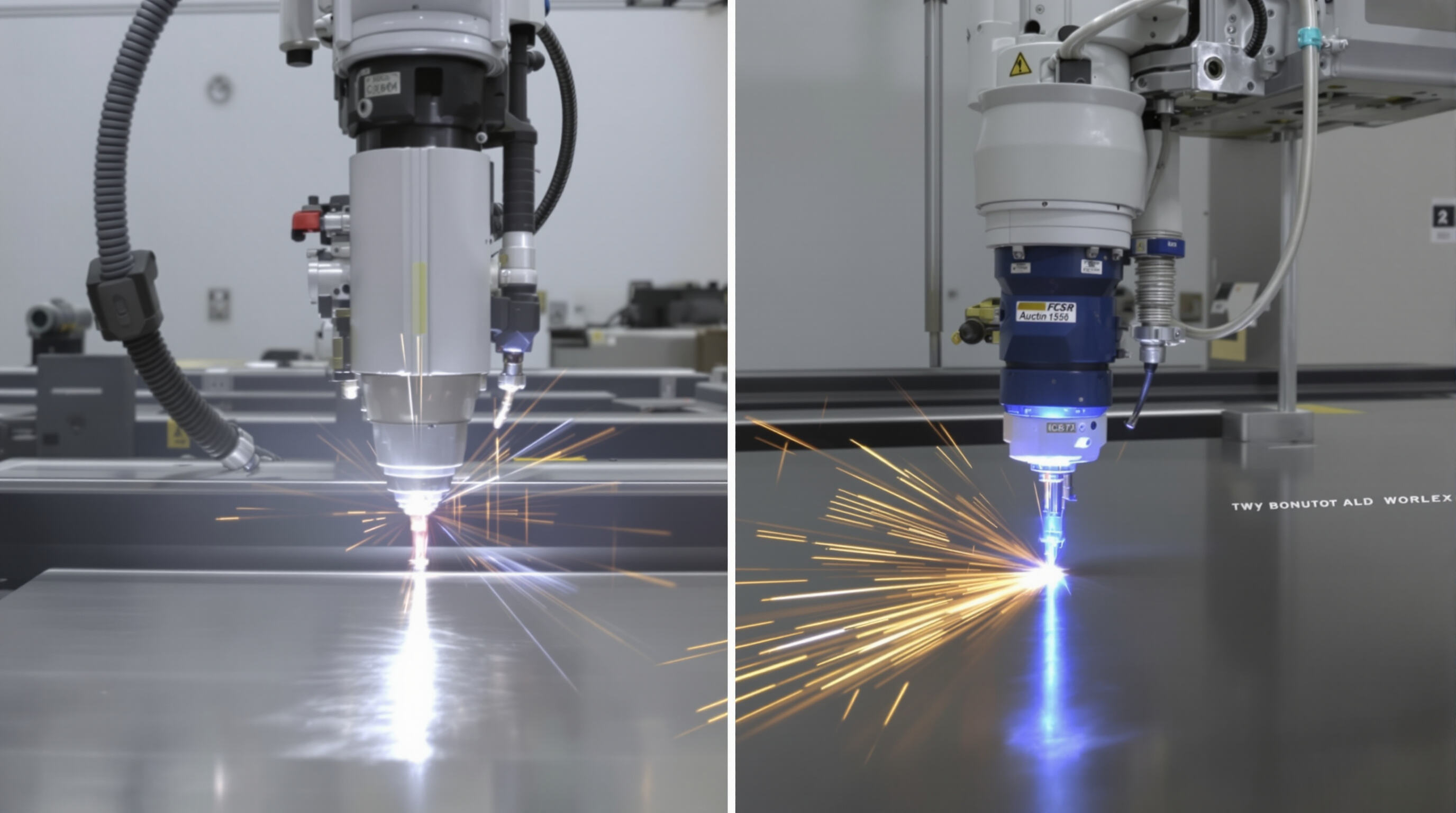

Laser welding equipment works by amplifying light into an intense beam capable of melting metal right where needed. When this concentrated energy hits the metal surface, it forms what's called a keyhole cavity. Basically, the metal gets vaporized and then collapses back together as everything cools down and bonds. One big advantage is how little heat spreads out during the process thanks to those super fast pulses, sometimes going over 100 times every single second. These beams travel through fiber optic cables and can hit accuracy levels as fine as 0.1 millimeters. That kind of precision makes these machines really valuable in industries like aerospace engineering and when manufacturing medical devices where tiny details matter a lot.

Traditional Welding Methods: Arc, MIG, and TIG Mechanisms Explained

Welding traditionally works by melting metal through electric arcs or burning gas. Arc welding creates really hot temperatures around 6,500 degrees Fahrenheit when electricity jumps between the electrode and what needs to be welded. For those looking to get things done quickly, MIG welding is popular because it feeds wire continuously while protecting the weld with special gases. But this speed comes at a cost since the wires need replacing all the time. Then there's TIG welding which gives much better control over the process thanks to its tungsten electrode that doesn't get used up during welding. The downside? Operators need quite a bit of training before they can master this technique. All these standard approaches tend to create larger areas affected by heat, making them risky choices for delicate projects where even small changes could cause problems like warping in thinner metals.

Key Differentiators: Energy Source, Heat Control, and Process Automation

Laser welding differs fundamentally from conventional methods in three areas:

- Energy Source: Lasers provide energy densities 10–100 times greater than arc processes, enabling deeper penetration with minimal surface damage.

- Heat Control: Integrated with robotics and programmable controls, laser systems achieve better focus and reduced heat-affected zones, minimizing the risk of material distortion.

- Process Automation: With integration into automated systems, laser machines provide precision, repeatability, and enhanced efficiency, lowering the risk for human errors and increasing throughput significantly.

Key Differentiators: Energy Source, Heat Control, and Process Automation

Laser welding differs fundamentally from conventional methods in three areas:

- Energy Source: Lasers provide energy densities 10–100 times greater than arc processes, enabling deeper penetration with minimal surface damage.

- Heat Control: The reduced heat spread in laser welding helps avoid damage to heat-sensitive areas and reduces the possibility of distortions.

- Process Automation: Integrated with robotics and programmable controls, laser systems provide high precision and efficiency, a key priority in many modern industries.

Case Study: The Automotive Industry’s Shift to Laser Welding Machine Systems

Many car manufacturers now use laser welding when putting together the body structure of vehicles, finding it advantageous due to its high speed and precision, allowing for faster production and cost savings. Laser systems eliminate contact with materials, reducing wear and adjustment needs during assembly. Cars are produced more efficiently and with superior results, meeting the demands of large-scale production.

Precision and Quality: Why Laser Welding Machine Technology Excels

Minimizing the Heat-Affected Zone (HAZ) for Reduced Material Distortion

Laser welding equipment works by minimizing the heat-affected zone, which results in less material distortion. This precision makes it suitable for thin metals like aluminum and stainless steel, which are often used in automotive and delicate applications. The minimized thermal impact ensures that sensitive metal components won't warp, maintaining their structural integrity.

Meeting Micro-Welding Demands in Electronics and Medical Device Manufacturing

As technology advances and microelectronics become more essential, the need for ultra-precise welding increases. Laser systems meet these demands, providing reliable, micro-scale welds necessary for tightly sealed, highly sensitive devices like pacemakers and cutting-edge electronic gadgets. These systems help avoid the flaws and material issues that traditional methods may cause, such as cracks during welding.

Adjustable Processing for Diverse Applications

Laser welding works exceptionally well for fine detailing but might be overkill for larger, more structurally simple tasks. For example, in cases involving thicker metal pieces, less precision might be sufficient, allowing for the cheaper and faster traditional MIG welding methods.

Speed, Efficiency, and Integration in High-Volume Production

Laser welding machines redefine production scalability by combining rapid, precision welding with seamless integration into automated systems, providing unparalleled speed and efficiency in high-volume production environments.

On-the-Fly Production and Efficiency

Fiber laser systems enable uninterrupted welding processes, removing the need for constant replacement of electrodes or repositioning. This continuous operation boosts production time and helps maintain a 98% uptime rate in high-demand manufacturing settings.

Robotic Automation: The Future of Laser Welding

Through the integration of laser systems with Robotics and Manufacturing Execution System (MES) software, high-volume production has achieved new efficiency levels. Live data feeds enable predictive maintenance and enhanced quality control, significantly reducing inspection times and production delays.

FAQ

What is laser welding and how does it work?

Laser welding works by using concentrated beams of light to melt and unite metals precisely, forming strong bonds without excessive heat dispersion.

What are the advantages of laser welding over traditional methods?

Laser welding offers greater precision with minimal heat-affected zones, reducing material distortion and allowing deeper penetration. It's also highly efficient and easily integrated with robotic automation, especially beneficial for high-volume production.

In which industries is laser welding particularly beneficial?

It's especially valuable in aerospace, automotive, battery manufacturing, and medical devices due to its precision and efficiency.

What is the initial cost comparison between laser welding and traditional methods?

Initial costs are higher for laser systems compared to traditional MIG or TIG setups, around three to five times more. However, savings from energy efficiency, lower maintenance, and reduced rework can lead to cost parity within 18–30 months.

When might traditional welding methods be preferred?

Traditional methods like MIG welding are often preferred for heavy fabrication tasks where the precision of laser welding is unnecessary and does not justify the higher cost.

Table of Contents

-

Laser Welding Machine of Core Principles and Technological Differences

- How Laser Welding Machine Technology Works: From Beam Focus to Fusion

- Traditional Welding Methods: Arc, MIG, and TIG Mechanisms Explained

- Key Differentiators: Energy Source, Heat Control, and Process Automation

- Key Differentiators: Energy Source, Heat Control, and Process Automation

- Case Study: The Automotive Industry’s Shift to Laser Welding Machine Systems

- Precision and Quality: Why Laser Welding Machine Technology Excels

- Speed, Efficiency, and Integration in High-Volume Production

- FAQ

- What are the advantages of laser welding over traditional methods?

- In which industries is laser welding particularly beneficial?

- What is the initial cost comparison between laser welding and traditional methods?

- When might traditional welding methods be preferred?