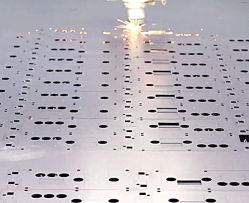

As quality, efficiency, and consistency become increasingly demanded, our robotic laser welder stands as the ultimate solution for all serious manufacturing. Combining advanced fiber laser technology with fully integrated robotics, the system gives flawless, high-speed welds to eliminate human error and put out maximum production.